Seismic Repair and Strengthening of Concrete Columns with Glass or Carbon FRP

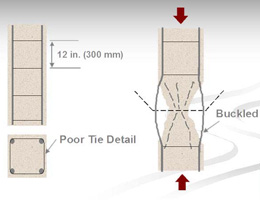

Reinforced Concrete columns or bridge piers can be efficiently strengthened with Glass FRP (GFRP) or Carbon FRP (CFRP). Older (pre-1970s) columns have two major shortcomings; they are inadequately confined (usually a No. 3 or 4 tie placed at a spacing of 12 inches) and the ends of the ties are not properly anchored in the core region. During an earthquake, the ties open and allow the longitudinal steel to buckle, leading to failure of the column. |

|

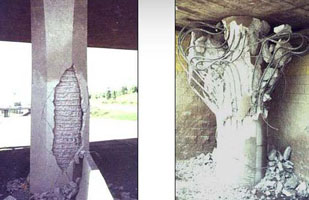

Glass FRP and Carbon FRP can provide significant lateral confinement for concrete columns or bridge piers. While spiral columns have in general performed well in past earthquakes, the above shortcomings have resulted in failure of many tied columns such as the one shown on the right. |

|

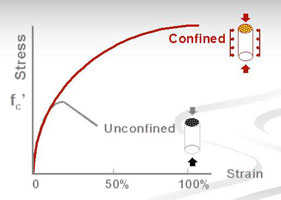

The solution is to externally confine the column. External confinement increases the strength of the concrete, but more importantly for seismic applications, the strain at failure of the concrete (i.e. ductility) increases significantly. Among the advantages of retrofitting columns with Fiber Reinforced Polymer (FRP) are: |

|

|

Research and Development

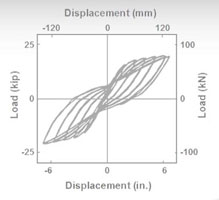

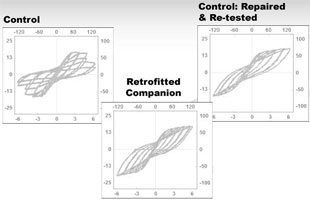

QuakeWrap principals were the first research team in the U.S. to receive a 3-year grant from the National Science Foundation in 1991 to study the behavior of columns retrofitted with fiber composite jackets. Both repair and retrofit of circular and rectangular columns with active and passive confinement were examined. The findings of this extensive study have been published in several journal articles dealing with such topics as confinement effects on circular and rectangular columns and repair of earthquake-damaged columns. A number of other researchers have also studied this problems and a sample of those technical papers is also available. |

|

.Columns were subjected to an axial load of 100 kips that remained constant throughout the test while the top of the columns were subjected to reversed cyclic loading, simulating earthquake motions. Retrofitted specimens continued to resist additional lateral loads during consecutive loading cycles and testing usually had to be stopped because the maximum displacement of the testing equipment was reached. |

Case Studies

A sample of projects where Fiber Reinforced Polymer (FRP) have been used to strengthen reinforced concrete columns are listed below. By clicking on each project, you will be able to view specific information on each project.

- Anchorage International Airport, Seisimic Strengthening of Walls and Columns with Carbon FRP, Anchorage, AK

- Bay View Bridge, Carbon FRP Repair Of Underwater Bridge Piers, Ft. Lauderdale, FL

- BMC Parking Structure, FRP Strengthening of Corbels in Parking Structure, Phoenix, AZ

- Cabana Hotel, FRP Strengthening Of Concrete Columns In Historic Hotel Building, Miami Beach, FL

- Cleveland Columns, FRP Confinement of Concrete Columns, Port Clinton, Ohio

- Interstate 40 (I-40) Bridge, FRP Retrofit of Bridge Piers Subjected to Corrosion Damage, Oklahoma City, OK

- Interstate 70 (I-70) Overpass, FRP Repair of Bridge Piers Subjected to Impact Damage, Kansas City, MO

- Interstate 90 (I-90) at Cline Ave. Bridge, FRP Retrofit of Rectangular Bridge Piers, Gary, IN

- Interstate 94 (I-94) at S.R. 49, FRP Repair of Circular Bridge Piers, Chesterton, IN

- Phoenician Resort, FRP Retrofit of Concrete Frames in Parking Structure, Scottsdale, AZ

- Plaza in Clayton, FRP Retrofit of Concrete Columns in Condominium Tower, St. Louis, MO

- Rocky Mountain Hardware Warehouse, FRP Strengthening of R/C Columns in Cold Weather Conditions, Hailey, ID

- Tucson Main Library, FRP Repair of Corroded Pedestals of a Cooling Tower, Tucson, AZ