Concrete Beam Strengthened with Glass or Carbon FRP

Glass Fiber Reinforced Polymer (GFRP) or Carbon FRP are economical and efficient materials for strengthening concrete beams for flexure and shear. Among the advantages of GFRP and CFRP are:

- Increased flexural strength for both positive and negative moment regions

- Increased shear strength

- Increased stiffness at service loads

- Reduced cracked widths for enhanced durability and corrosion resistance

- No reduction in overhead clearance (e.g. in parking garages)

- Lower cost than conventional methods

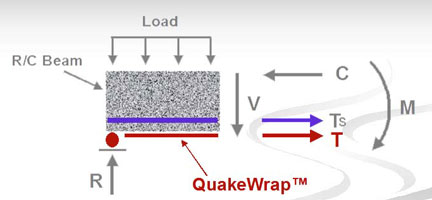

Because the moment capacity of a section is the couple resulting from the tensile and compressive forces, FRP can be applied to the tension face of the beam to increase the tension force. In most case, the deck or floor slab does have sufficient compressive strength and does not require strengthening. However, if needed, FRP can also be added to the compression face of the beam. In some of the pioneering studies carried out in the late 1980s by the principals of QuakeWrap, Inc, it was clearly shown that improper epoxies can result in FRP retrofits that add little to the strength of the beam. These studies formed the basis for several years of additional R&D that resulted in the development on QuakeBond™ epoxies. |

|

Tests of reinforced concrete beams strengthened with glass and carbon FRP have demonstrated that when appropriate epoxies are used, failure will not take place in the bond line; instead, similar to reinforced concrete flexural members, one can proportion the design such that failure is reached in concrete after yielding of the longitudinal steel reinforcement. This is particularly important because the yielding of steel can provide the necessary ductility that lacks in the behavior of FRP products. |

|

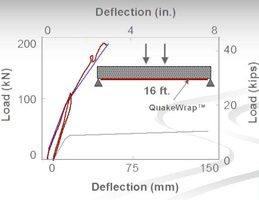

The load-deflection of a typical reinforced concrete beam is shown here; the grey line shows the predicted response of a similar unretrofitted beam. The red line is the actual laboratory-measured response of the concrete beam retrofitted with glass FRP and the blue line is the predicted behavior based on the analytical model that was developed and published in the ASCE Journal of Structural Division. As can be seen, our analytical model predicts the behavior of the retrofitted beam very accurately. A number of other beams were also tested as a part of this study under the supervision of QuakeWrap principals and these results are also available in Technical Papers written by various researchers. |

Load Vs. Deflection of R/C Beam |

Shear in concrete beams is resisted by tension forces in stirrups or ties. FRP can be bonded to the sides of a beam or column to increase its shear strength. Extensive studies conducted under the guidance of the principles of QuakeWrap at the Federal Highway Administration laboratories have demonstrated the feasibility of shear strengthening with FRP. Other researchers have conducted similar studies and have offered design guidelines for beams strengthened with FRP for shear and flexure. Some of these papers are available under the technical papers section of this web site.

.

Case Studies

A sample of projects where R/C beams have been strengthened with Fiber Reinforced Polymer (FRP) are listed below. By clicking on each project, you will be able to view specific information on each project.

- Apple Computer Store, Carbon FRP Strengthening Of Concrete Slabs, Glendale, CA

- Art Gallery, FRP Retrofit of Reinforced Concrete Beams in Historic Building, Phoenix, AZ

- Challenger Middle School, FRP Repair of Bridge Beams, Tucson, AZ

- City Court Garage, FRP Repair of Reinforced Concrete Beams in Parking Structure, Tucson, AZ

- Dallas Roberts Elementary, FRP Strengthening of Prestressed Concrete Beams in School Gym, Dallas, TX

- Fox Historic Theater, FRP Retrofit of Historic Building, Tucson, AZ

- FRP Strengthening of Concrete Slab in Medical Center Tucson, Strengthening of Concrete Slab under MRI, Tucson, AZ

- FRP Strengthening of prestressed DT beams in parking garage, FRP Strengthening of prestressed DT beams in parking garage, Phoenix, AZ

- Oceans One Condominium, FRP Repair of Concrete Beams in Condominium Building, Daytona, FL

- Panorama Condominiums, FRP Repair of Prestressed Concrete Beams in Parking Structure, Las Vegas, NV

- Plaza de Diego High-rise, FRP Retrofit of Concrete Floor System in High Rise Building, San Juan, PR