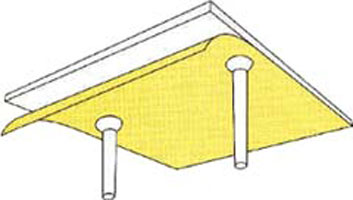

Slabs Strengthened with Fiber Reinforced Polymer (FRP)

Glass or Carbon FRP is a cost-effective system for strengthening concrete floors and decks or correcting design and construction errors that have lead to excessive deflection and sag in the slab. The case history below highlights one such application.

Among the advantages of Fiber Reinforced Polymer (FRP) for strengthening slabs are:

- Increased flexural strength for both positive and negative moment regions in the slab

- Increased slab stiffness and reduced deflections at service loads

- Reduced crack widths for enhanced durability

- Covering a fraction of the slab surface with FRP may be sufficient for strengthening the entire slab

- No reduction in overhead clearance is caused by application of FRP (e.g. in parking garages)

- Lower cost for FRP compared to strengthening with conventional methods (e.g. epoxy injection in cracks).

.

Glass or Carbon FRP are very effective in repair and strengthening of slabs and decks. Because the moment capacity of the slab or deck is the couple resulting from the tensile and compressive forces, FRP can be applied to the tension face of the beam to increase the tension force. In most cases, the deck or slab has sufficient compressive strength and does not require strengthening. However, if needed, FRP can also be added to the compression face of the beam as a part of strengthening and repair. In some of the pioneering studies carried out in the late 1980s by the principals of QuakeWrap, Inc, it was clearly shown that improper epoxies can result in retrofits that add little to the strength of the beam. These studies were the basis of several years of additional R&D resulting in the development of QuakeBond™ epoxies.

Case Study

Five-story Building, Westwood, CA

.

The slab on the first floor of this building had deflected excessively and needed to be strengthened and flattened. FRP offered many advantages for the repair and strengthening of this structure. The options of introducing new concrete or steel beams below the slab were ruled out because such strengthening would reduce the overhead clearance in the parking garage significantly.

For strengthening with FRP, the slab was temporarily shored up while certain areas on the bottom and top surfaces of the slab were reinforced with a glass fabric FRP. After curing of epoxy, shoring was removed and the floor surface was leveled with a lightweight leveling grout. The tension forces in the FRP kept the slab flat after removal of shoring, similar to post-tensioning the slab. During this repair and strengthening project with glass FRP, none of the numerous pipes that were hung from the slab needed to be removed and the overhead clearance in the parking area was hardly reduced.

A sample of other projects where Fiber Reinforced Polymer (FRP) have been used to strengthen reinforced concrete slabs are listed below. By clicking on each link, you will be able to view specific information on that project:

- Apple Computer Store, Carbon FRP Strengthening Of Concrete Slabs, Glendale, CA

- FRP Strengthening of Concrete Slab in Medical Center Tucson, Strengthening of Concrete Slab under MRI, Tucson, AZ

- Georgian Towers, Punching Shear Reinforcement with FRP, Silver Spring, Maryland

- Holy Cross, Slab strengthening around opening, Silver Spring, Maryland

- LA Museum of Natural History, Seismic Retrofit of Historic Museum with Carbon FRP, Los Angeles, CA

- Plaza de Diego High-rise, FRP Retrofit of Concrete Floor System in High Rise Building, San Juan, PR

- Providence Hospital, FRP Strengthening of Concrete Slab in Health Care Facility, Anchorage, AK

- St. Josephs Medical Center, Strengthening Concrete Slabs with NSM Carbon FRP Laminates, Phoenix, AZ

- Trump Grande Condominiums, FRP Repair of Concrete Slab in High Rise Building, Sunny Isles Beach (Miami), FL