Strengthening of Steel Bridge Girders with Carbon FRP

Carbon Fiber Reinforced Polymer (CFRP) is an economical and efficient system for flexural strengthening of steel bridge girders. Among the advantages of repair and strengthening of steel beams and girders with FRP are:

- Increased flexural strength in the steel girder for both positive and negative moment regions

- Restores steel girder capacity after loss of tension flange area due to corrosion

- Increased stiffness of the steel girder in both elastic and plastic response

- Eliminates stress concentration in the steel girder due to welding

- Improved fatigue behavior of steel bridge girder (after retrofit with FRP)

- Lower cost than conventional methods

The feasibility of strengthening of steel bridge girders with carbon FRP was demonstrated through an extensive research study at the University of Arizona. The girders were constructed using W14x30 steel sections and as shown in the above photos, spanned 16 feet (4.8 m) during the test. |

|

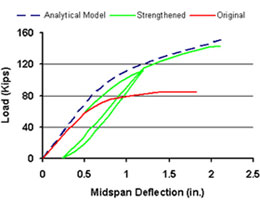

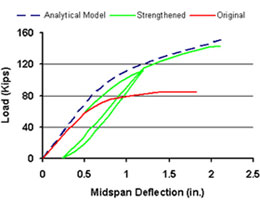

To simulate prior damage, the area of the tension flange for the beam or girder was reduced by 25%. The load-deflection for that damaged beam is shown in red. The tension flange of a similar companion beam was strengthened by applying 3 strips of Carbon Fiber (CFRP). The behavior of the steel beam or girder strengthened with carbon FRP is shown in the graph below.

|

|

As can be seen, the strength of the bridge steel girder that was retrofitted with carbon FRP was significantly increased; this was also accompanied by a profound increase in stiffness of the girder in the plastic region.

Carbon Fiber Reinforced Polymer (CFRP) also improves the fatigue behavior of the structure; the CFRP retrofitted beams could resist 2½ – 3½ times more cycles of loading compared to the cracked bridge steel girders that were not retrofitted with carbon FRP. |

|